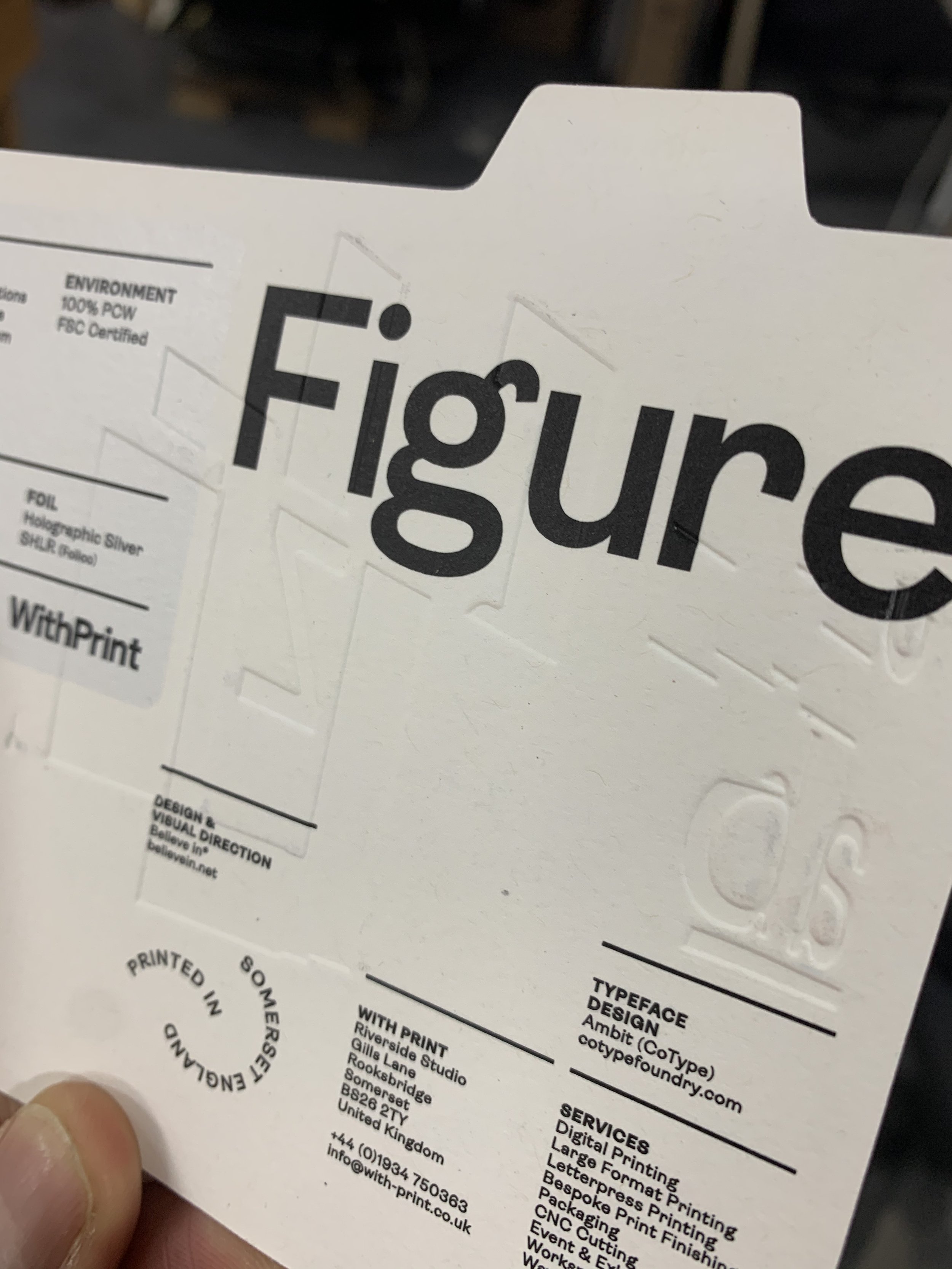

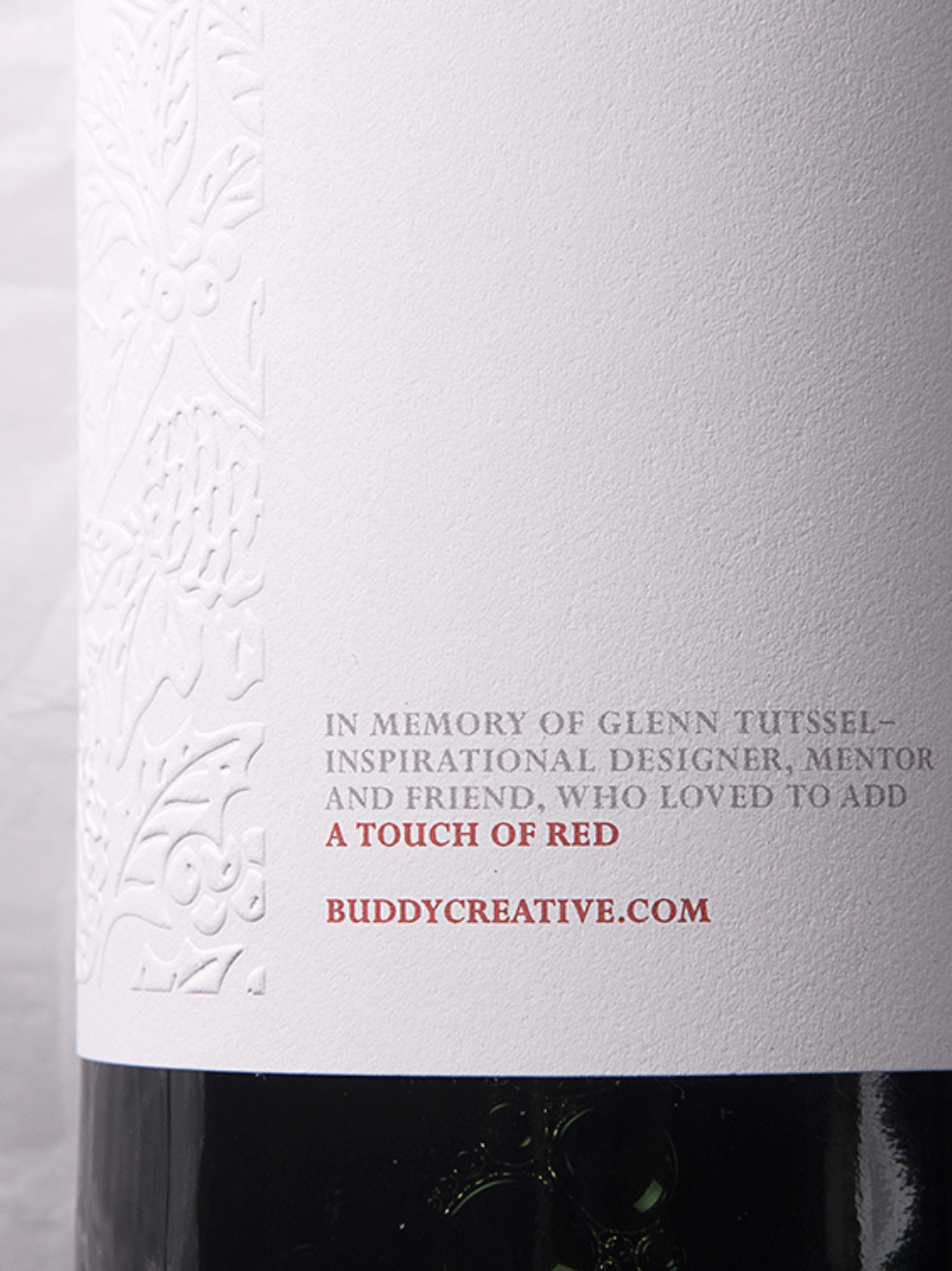

Emboss / Deboss

We actually have 2x Heidelberg platens and use both of these for our luxury embellishments including embossing or debossing.

Embossing is when a raised effect is added to a sheet. This involves a male and female die forme that shapes the sheet between it.

Debossing is when the design is pushed down into the paper. This involves just one die forme and can sometimes be more successful than embossing as more pressure can be added. But please be aware that when more pressure is added it can show through the back of the sheet.

If you want to see some examples then request a sample pack here.

Tech Tip:

Like foiling, when embossing or debossing we can feed up to SRA3 (460mm x 320mm) size sheets. Both styles use a hot stamping process which involves a metal die that is machined to your design. We have the same limitations that we have with the foiling process. So font sizes and fine lines may need to be increased to make sure we can match your expectations. The die formes can take 3-5 days to produce. We will always try to work with you and advise if any changes might be required.